In the realm of custom apparel printing, DTF transfers have rapidly gained attention for their innovative approach and impressive results. This Direct to Film (DTF) printing technique allows for vivid designs to be printed onto specialized films, which can then be seamlessly applied to fabric using a heat press. Compared to traditional methods like screen printing and heat transfer vinyl, DTF offers unmatched versatility and detail, making it a top choice for designers and clothing manufacturers alike. This blog will delve into the unique advantages of DTF transfers, highlighting their durability and cost-effectiveness in the competitive landscape of custom apparel. Join us as we explore how DTF printing stands out among other techniques such as Direct to Garment (DTG) printing, offering high-quality solutions to a diverse range of fabric types.

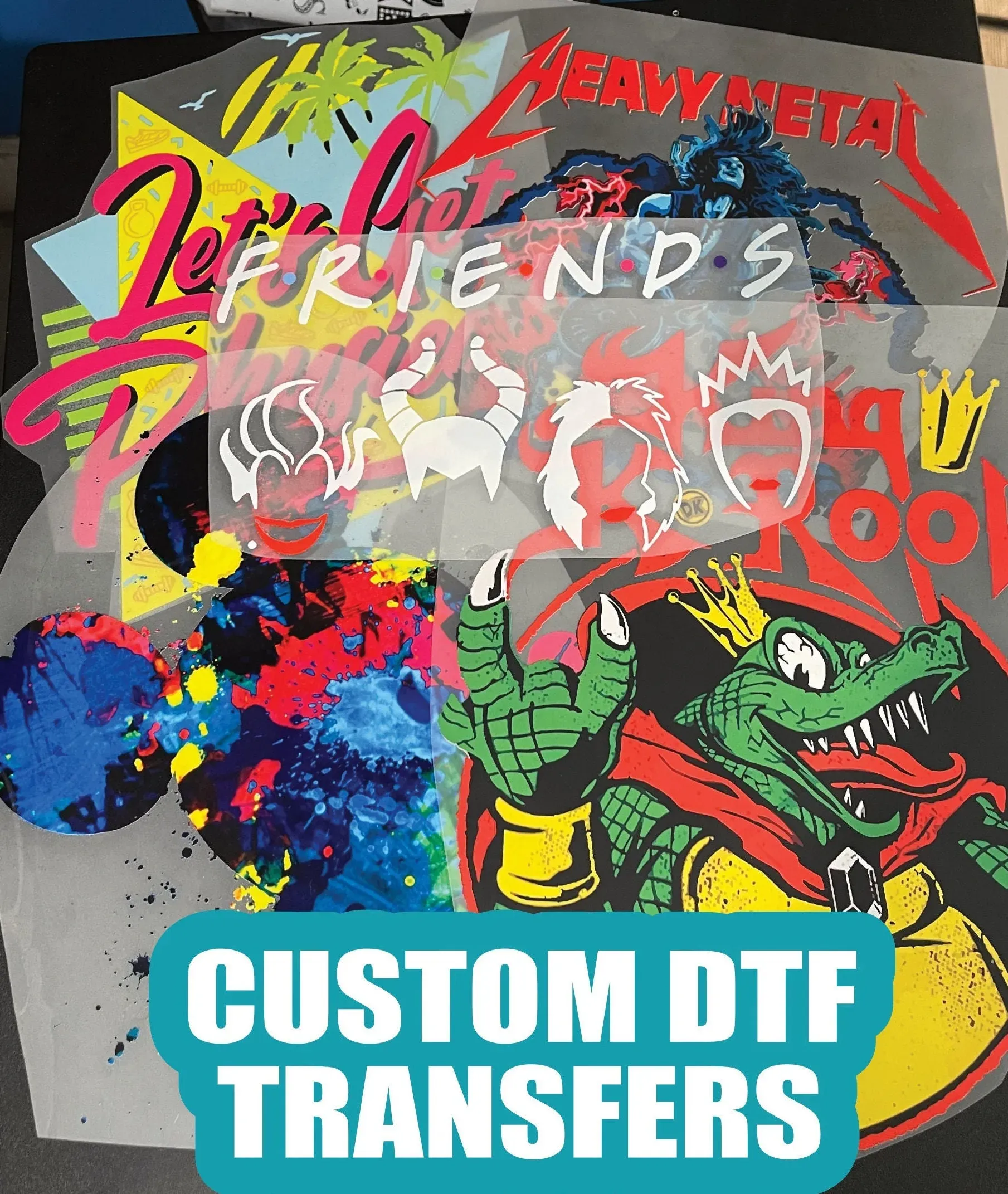

When we talk about DTF transfers, we’re referring to a cutting-edge method known as Direct to Film printing that is revolutionizing the way designs are applied to fabrics. This technique offers a fresh alternative to more traditional processes like screen printing and heat transfer vinyl, which have dominated the custom apparel industry for years. With its ability to deliver intricate designs and vibrant colors, DTF printing serves as an effective solution for businesses looking to make a statement with their products. Additionally, the efficiency it brings to the printing process enhances its appeal for small and large orders alike. As we dive deeper into DTF transfers, it becomes clear that this modern method is shaping the future of custom apparel printing.

Understanding DTF Printing Techniques

DTF printing, or Direct to Film printing, revolutionizes the way designs are transferred onto garments. This technique uses advanced inkjet technology to print vibrant images on a thin film, which is then applied to the fabric through a heat press. Unlike older methods such as screen printing or heat transfer vinyl (HTV), DTF printing allows for an extensive color palette and intricate detailing, which is crucial for modern apparel designs. This method is not only versatile, as it works on various materials including cotton, polyester, and blends, but it also opens up possibilities for stunning custom designs that cater to diverse customer preferences.

The process itself involves several steps, starting with the creation of digital designs that are printed onto the film. After the printing phase, a powder adhesive is applied, followed by a heating process to bond the ink to the adhesive. Lastly, the film is heat pressed onto the garment, ensuring a durable and long-lasting print. The intricacies of this method make it an appealing option for small businesses and individuals aiming to create unique apparel without the high initial costs associated with traditional screen printing setups.

Comparative Analysis: DTF Transfers vs. Screen Printing

When it comes to custom apparel printing, screen printing has been a longstanding method favored for its effectiveness in high-volume jobs. However, when comparing screen printing to DTF transfers, significant differences emerge, particularly in terms of setup and versatility. Screen printing requires individual screens for each color, which can lead to higher production costs and longer lead times. In contrast, DTF transfers streamline this process, allowing for quick adjustments and the ability to print multicolor designs without the logistical complications associated with traditional screens.

Furthermore, screen printing often struggles with detail and color vibrancy in comparison to DTF. The DTF method shines in its capacity to reproduce intricate designs with fine details and rich color gradients that other methods may not handle as effectively. As businesses work to offer more customized and diverse product options, the advantages of DTF printing become increasingly apparent, positioning it as a strong alternative to traditional screen printing.

DTF vs. Direct to Garment (DTG) Printing

Direct to Garment (DTG) printing is another popular technique in the realm of apparel customization, primarily known for its ability to print detailed images onto fabrics. However, DTF printing presents an attractive option with its unique benefits tailored for different applications. While DTG has gained a reputation for high-detail work, it typically comes with higher costs, especially in bulk production. DTF transfers not only offer a cost-effective alternative but also enhance durability and fabric compatibility, making it a smarter choice for varying garment types.

Moreover, one of DTF printing’s standout features is its speedy production turnaround. As DTG equipment can be slower due to the need for multiple passes and specific fabric requirements, DTF printing can adapt more quickly to demand, particularly beneficial for businesses that require agility in fulfilling customer orders. This efficiency, combined with quality, positions DTF as a competitive technique alongside DTG, justifying its rapid growth within the custom printing industry.

The Benefits of DTF Transfers in Custom Apparel

DTF transfers come with a plethora of advantages that make them appealing in custom apparel printing. One of the most noteworthy benefits is the adaptability to different fabric types, granting businesses the flexibility to create diverse clothing products, from t-shirts to jackets, without compromising on print quality. This versatility not only helps in catering to a larger audience but also opens up opportunities for creative designs that can resonate with various demographics.

Additionally, DTF printing boasts impressive durability, ensuring that designs maintain their vibrancy and integrity even after multiple washes. This durability is a significant selling point for customers who prioritize longevity in their apparel investments. Therefore, businesses leveraging DTF technology can confidently market their products as high-quality, long-lasting garments, thus enhancing customer satisfaction and loyalty.

DTF Transfers: The Cost-Effectiveness Factor

Cost is a vital consideration when it comes to custom apparel printing, and DTF transfers offer a distinct advantage in this area. Unlike screen printing, which involves costly initial setup for screens, DTF printing eliminates the need for these expenses, making it an attractive option for businesses that cater to smaller orders or limited runs. With DTF, the process allows for just-in-time production without sacrificing quality, providing brands with a financial edge.

Furthermore, the efficient use of materials in DTF printing means that waste is significantly reduced compared to other printing techniques. This cost-effectiveness, combined with the ability to execute complex, multi-color designs, positions DTF as a key player in the evolving landscape of custom apparel printing—especially for startups and small enterprises looking to minimize costs while maximizing creative freedom.

Challenges in Embracing DTF Printing

Despite the numerous advantages DTF printing presents, it is essential to acknowledge the challenges that new users might face. Mastery of the DTF equipment and techniques may require a learning curve, which can be daunting for those unfamiliar with the technology. Gaining proficiency in managing the printing process, from ink selection to film application, is crucial to achieving consistent, high-quality results.

Another challenge is related to the initial investment in printing equipment and materials. For some, the upfront costs of high-quality printers and transfer films may pose a barrier to entry. Additionally, ensuring consistency in print quality can vary based on equipment and technique employed by the printers. As the landscape of DTF printing continues to evolve, it is important for new businesses to invest in proper training and reliable equipment to maximize the benefits of this innovative printing method.

Frequently Asked Questions

What makes DTF Transfers stand out compared to Direct to Garment printing?

DTF Transfers distinguish themselves from Direct to Garment (DTG) printing by offering greater versatility and cost-effectiveness, especially for smaller orders. While DTG excels in detailed designs, DTF can print on various fabric types without needing separate screens, making it ideal for mixed media and colorful graphics.

Are DTF Transfers more durable than screen printing?

Yes, DTF Transfers are generally more durable than screen printing. They provide excellent washability and resilience against fading, maintaining print quality even after multiple washes, which is a significant advantage over traditional screen printing methods.

Can I use DTF Transfers on any fabric type?

DTF Transfers can be applied to a wide range of fabric types, including cotton, polyester, and blended fabrics. This versatility allows printers to cater to diverse client needs, making it a preferred choice for custom apparel production.

How do DTF Transfers compare to Heat Transfer Vinyl (HTV)?

While Heat Transfer Vinyl (HTV) is great for simple designs, DTF Transfers excel at producing intricate and multicolored graphics. DTF technology allows for more detailed images and vibrant colors, which HTV may struggle to replicate, particularly on complex designs.

What is the cost-effectiveness of DTF Transfers for custom apparel printing?

DTF Transfers offer significant cost savings, especially for smaller batch custom apparel printing. Unlike screen printing, DTF eliminates the need for screen setups for each color, reducing initial costs and enabling economical printing of fewer items.

What are the latest trends in DTF Transfers for custom apparel printing?

Recent trends in DTF Transfers include advancements in printing equipment and transfer films, which enhance print quality and lower costs. This technology has become increasingly popular in e-commerce, facilitating fast production timelines and adaptability for various custom applications.

| Feature/Technique | DTF Transfers | Screen Printing | DTG Printing | HTV (Heat Transfer Vinyl) |

|---|---|---|---|---|

| Versatility | Compatible with various fabric types | Best for bulk orders; high setup cost limits smaller jobs | Excellent for variable runs but tends to be pricier | Excellent for simple graphics; struggles with complexity |

| Durability | Highly durable and withstands multiple washes | Durability varies; setup can degrade long-term quality | Pricey; may vary in washability and lifespan | May peel or fade over time; less durable than DTF |

| Cost Effectiveness | Lower setup costs for smaller orders | High initial costs due to screens; cost-effective for large orders | Generally more expensive, particularly for larger prints | Economical for smaller runs; costs increase with complexity |

| Detail & Color | High detail and vibrant colors attainable | Bold finish; lacks the detail and gradient options | High-detail but slower for quick turnarounds | Limited by the complexity of designs |

Summary

DTF Transfers represent a transformative innovation in the custom apparel printing landscape. With their superior versatility, durability, cost-effectiveness, and ability to reproduce intricate designs, DTF printing has distinctly set itself apart from traditional methods like screen printing, DTG, and HTV. As businesses increasingly adopt this technology, driven by advancements that simplify the process and enhance print quality, it is evident that DTF Transfers are not only reshaping the industry but also opening exciting new avenues for creativity and efficiency. The future of apparel printing looks bright with DTF leading the way.